Magnetic Coupling

![]()

Magnetic Couplings

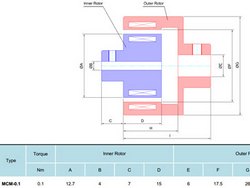

——0.1Nm to 17Nm Low Torque Magnetic Couplers

Q: Is there any drawings?

A: Our advantage is the low torque magnetic couplings. Leyuan Magnets has optimized the series size of magnetic coupler, and customers can make adjustments based on this.

Please check the details data of MCM 0.1-10Nm magnetic coupling.PDF (325KB)

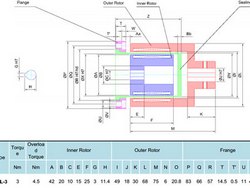

Please check the details data of MCL 3-80Nm magnetic coupling.PDF (370KB)

Q: Sample, price and lead time?

A: Magnetic coupling project always needs sample tested at the beginning, so we accept one sample order, but in order to screen out the customers with the intention of batch, we will charge a high sample fee. Torque from 0.1 Nm to 80 Nm, will charge 450 to 1200 USD sample fee, but sample fee will be totally refunded upon receipt of bulk order. Lead time is usually 35 days.

Q: What is quantities will be considered as bulk order? price?

A: We will quote according to the processing difficulty.

Q: Do you sell ready-made couplings?

A: Our magnetic couplings are all customized. For an example, a customer needs a different shaft, then we have to machine a new part for him, so we have no ready-made couplings in stock.

Q: Failure of magnetic coupling?

A: Magnetic coupling uses permanent magnets to transmit torque. The magnetic coupling fails when the permanent magnets are demagnetized or loss magnetism. The main methods of magnets failure are high temperature, vibration, reverse magnetized, etc., so our magnetic coupling must run in synchronous state. If the load is too heavy, the inner rotor stops or runs in asynchronous state, the reverse magnetic field will come from the outer rotor, it will reduce torque or complete damage the coupling.

Q: What should I pay attention to when installing the magnetic coupling?

A: Magnetic coupling is a non-contact transmission. Outer rotor and isolation, isolation and inner rotor have a certain gap, which greatly reduces the difficulty of installation. However, the wall thickness of the isolation is very thin, and if it is rubbed to other parts, the isolation will be destroyed, so a certain coaxiality hva to be ensured accordingly.

Q: How do I choose a model?

A: Firstly, torque of the small coupling is related to the rated power and rated speed of the motor. The rough calculation formula: coupling torque (Nm) = 10000 * motor power (kW) / motor speed (RPM); secondly, make sure working temperature, working pressure, corrosion level. Our magnetic couplings are made for speeds is under 3000 RPM and operating pressures is less than 2 MPa.

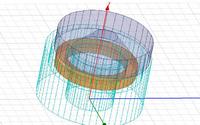

Q: How does a permanent magnet coupling work?

A: Permanent magnet coupling is also divided into various structural forms. Permanent magnet coupling we produced: under the principle of magnets attracted each other, the inner and outer rotors are assembled with super-strong magnets. When the motor drives the outer rotor, the energy is transmitted to the inner rotor through the magnetic circuit, so that the inner rotor rotates synchronously. This magnetic coupling achieves static sealing because the internal and external drive shafts are not hard-wired, they are widely used in transportation systems for corrosive, toxic, and contaminated liquids or gases.

Why Us:

- Deep understanding on magnets, We are very familiar with all kinds of magnets, compared with other magnet manufacturers, we can do quantitative calculation and optimization on magnetic circuit, for example, after customers designate the torque of magnetic couplings, we are able to offer the most optimal and cost-effective solution based on our calculation result.

- Experienced mechanical engineers involved. Mechanical engineers are essential in the team, because the mechanical performance, dimensional tolerance etc. are designed and verified by them, furthermore, they will make the most reasonable machining plan based on the resources of machining factory.

- The constant pursuit of consistency, There are many types of magnetic assemblies and the processes are complex. Take the gluing process for example, manual gluing varies from person to person, and the amount of glue cannot be controlled. The automatic glue dispenser on the market can not adapt to our products. For this reason, we design and make an automatic glue dispensing system by ourselves. it eliminates human factors.

- Skilled workers and continuous improvement!The assembly of magnetic couplings and magnetic assemblies can not be done without skilled assembly workers. We have designed and made a number of unique and delicate tooling & fixtures to reduce the labor intensity for workers, it not only improves working efficiency, but also further ensure product consistency.

![]()

![]() Listen to customers and understand their needs

Listen to customers and understand their needs

To fully understand the customer’s intention, in addition to the main performance indicators of the magnetic assemblies, we also consider their working environment, using methods and transport status. Master the most comprehensive information to prepare for sampling in the next step.

According to the customer’s needs, we assist them in calculating the design magnetic circuit, and initially consider the machining and assembly process. Based on our experience and calculation results, we make suggestions on customer’s design for further improvement, and finally reach an agreement with customers then sign sample orders.

First, based on our experience and CAE calculations, an optimal model is obtained. The key point of the model is to use the minimum amount of magnets and magnet shapes are easy to machine. On this basis, our engineers will comprehensively consider the model structure which must be easy to machine and assemble. Then we sort out our opinions and communicate with customers, and finally sign sample orders.

First, based on our experience and CAE calculations, an optimal model is obtained. The key point of the model is to use the minimum amount of magnets and magnet shapes are easy to machine. On this basis, our engineers will comprehensively consider the model structure which must be easy to machine and assemble. Then we sort out our opinions and communicate with customers, and finally sign sample orders.

![]() Formulating process and sampling

Formulating process and sampling

To formulate the specific process and increase quality monitoring points, create drawings for the breakdown structure of magnetic couplings then start production, and design tooling & fixtures:

1. To ensure the part’s geometric and dimensional tolerances;

2. For the use of measuring equipment to ensure quality.

This is an example of an inspection equipment we specially designed. After signing the sample order, according to the process and assembly characteristics , we have to formulate a detailed process to increase the quality monitoring in key processes. At the same time, we make tooling & fixtures which serves two purposes: first,it is to ensure the geometric and dimensional tolerances of the parts and the entire product at this stage . and second, it is for parameter testing, and we must ensure that our products can be tested quickly and efficiently in subsequent batches.

This is an example of an inspection equipment we specially designed. After signing the sample order, according to the process and assembly characteristics , we have to formulate a detailed process to increase the quality monitoring in key processes. At the same time, we make tooling & fixtures which serves two purposes: first,it is to ensure the geometric and dimensional tolerances of the parts and the entire product at this stage . and second, it is for parameter testing, and we must ensure that our products can be tested quickly and efficiently in subsequent batches.

After receiving the batch orders, we will reasonably arrange the working positions and procedures for workers, then operation begins, when necessary, we will design and make the unique tooling & fixtures to reduce the labor intensity for workers and ensure the consistency of batch production.

Magnets separating/splitting equipment

Magnets separating/splitting equipment

Permanent magnet couplings, motor magnets and some magnetic assemblies require magnets to be assembled after magnetization. The efficiency of manual magnet splitting is low. The most important thing is that workers’ fingers are very painful to peel off magnets for a long time. For this reason, we designed and made this magnets separating/splitting equipment which completely relieves workers from pain and improves efficiency.

Glue is used to bond strong magnets and other parts together in most magnetic couplings and magnetic assemblies, usually manual gluing varies from person to person, and the amount of glue cannot be controlled, therefore, we designed and made automatic glue dispensing equipment that is exclusively for our product, compared with other glue dispensers sold on the market, ours works more efficiently and quickly.

Automatic laser welding machine

Automatic laser welding machine

Many products require laser welding. The purpose of doing so is to seal (magnets need to be completely sealed for some magnetic assemblies). In actual welding, workpieces have tolerances and welding has thermal deformation, however, our automatic laser welding machine can offer better weld strength, tighter precision, and minimal deformation for our bulk orders, we designed and made a lot of special tooling & fixtures, so even new workers also can quickly get started.

We just listed a small number of tooling & fixtures mentioned above, there still are many similar special tooling & fixtures with us. All of these are to reduce labor and improve efficiency while minimizing the effects of human operations. We have rich experience in production control. We do quantitative control in all processes so that the consistency can be ensured for each batch of products. In the current situation where workers are difficult to recruit and labor costs are rising sharply, we are pursuing high-quality products with minimal labor and continuous improvement is our goal.

Ask for a quote

![]()

People who visited this page also visited these LEYUAN pages: