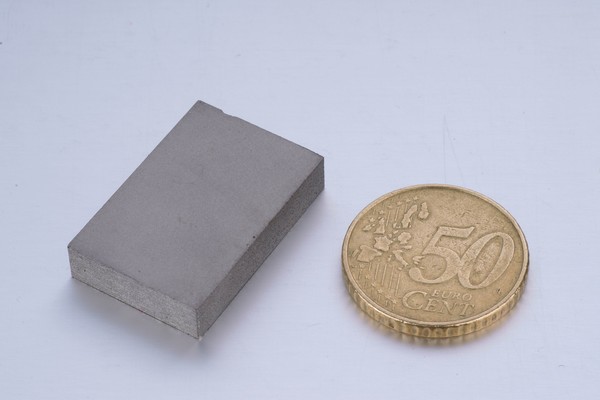

SmCo Magnets

![]()

Features:

SmCo magnet is a rare earth metal samarium and cobalt-based strategy elements, with iron, copper, zirconium, praseodymium and other metal materials ratio of melting into the alloy, grinding, pressing, sintering and aging made of a magnetic materials with higher magnetic properties (high energy product, high coercivity, high remanence); very low temperature coefficient (-0.030% / °C), high temperature (maximum temperature is 350 °C), negative temperature limitation, the working temperature above 180 °C, the maximum energy product, temperature stability and chemical stability are more than NdFeB material; has a strong anti-corrosion and oxidation resistance.

Applications:

Sintered Samarium Cobalt Magnet (SmCo) is characterized by high magnetic properties, outstanding thermal stability and excellent corrosion resistance ability. These characteristics make SmCo the ideal material in applications like aerospace ,microwave parts ,auotmobile parts, meters ,servo-motors, pump couplings, radar and sensors, particularly where the magnet is required to work at high temperature in a corrosive environment.

Magnetic Properties

| Grade | Br | Hcb | Hcj | BH(max) | WT | |||||

| KGs | T | kOe | kA/m | kOe | kA/m | MGOe | kJ/m³ | ℃ | ||

| SmCo5 | XG16 | 7.7-8.6 | 0.77-0.86 | 7.7-9.0 | 613-716 | ≥15 | ≥1194 | 15-18 | 120-143 | 250 |

| XG16H | 7.7-8.6 | 0.77-0.86 | 7.7-9.0 | 613-716 | ≥20 | ≥1592 | 15-18 | 120-143 | ||

| XG18 | 8.1-9.2 | 0.81-0.92 | 8.0-9.5 | 637-756 | ≥15 | ≥1194 | 17-20 | 135-159 | ||

| XG18H | 8.1-9.2 | 0.81-0.92 | 8.0-9.5 | 637-756 | ≥20 | ≥1592 | 17-20 | 135-159 | ||

| XG20 | 8.5-9.5 | 0.85-0.95 | 8.0-9.5 | 637-756 | ≥15 | ≥1194 | 19-22 | 151-175 | ||

| XG20H | 8.5-9.5 | 0.85-0.95 | 8.0-9.5 | 637-756 | ≥20 | ≥1592 | 19-22 | 151-175 | ||

| XG22 | 8.9-10.0 | 0.89-1.00 | 8.3-9.7 | 661-772 | ≥15 | ≥1194 | 21-24 | 167-191 | ||

| XG22H | 8.9-10.0 | 0.89-1.00 | 8.3-9.7 | 661-772 | ≥20 | ≥1592 | 21-24 | 167-191 | ||

| Sm2Co17 | XGS24M | 9.2-10.4 | 0.92-1.04 | 4.0-9.9 | 318-788 | 5.0-15.0 | 398-1194 | 22-25 | 175-199 | 350 |

| XGS24 | 9.2-10.4 | 0.92-1.04 | 8.3-10.0 | 661-796 | 15.0-25.0 | 1194-1990 | 22-25 | 175-199 | ||

| XGS24H | 9.2-10.4 | 0.92-1.04 | 8.3-10.1 | 661-804 | >25.0 | >1990 | 22-25 | 175-199 | ||

| XGS26M | 10-10.6 | 1.00-1.06 | 4.0-10.0 | 318-796 | 5.0-15.0 | 398-1194 | 24-27 | 191-215 | ||

| XGS26 | 10-10.6 | 1.00-1.06 | 8.5-10.3 | 677-820 | 15.0-25.0 | 1194-1990 | 24-27 | 191-215 | ||

| XGS26H | 10-10.6 | 1.00-1.06 | 8.5-10.3 | 677-820 | >25.0 | >1990 | 24-27 | 191-215 | ||

| XGS28M | 10.4-11.0 | 1.04-1.10 | 4.0-10.1 | 318-804 | 5.0-15.0 | 398-1194 | 26-29 | 207-231 | ||

| XGS28 | 10.4-11.0 | 1.04-1.10 | 8.5-10.3 | 677-820 | 15.0-25.0 | 1194-1990 | 26-29 | 207-231 | ||

| XGS28H | 10.4-11.0 | 1.04-1.10 | 8.5-10.3 | 677-820 | >25.0 | >1990 | 26-29 | 207-231 | ||

| XGS30M | 10.7-11.2 | 1.07-1.12 | 4.0-10.1 | 318-804 | 5.0-15.0 | 398-1194 | 28-31 | 223-247 | ||

| XGS30 | 10.7-11.2 | 1.07-1.12 | 8.8-10.4 | 700-828 | 15.0-25.0 | 1194-1990 | 28-31 | 223-247 | ||

| XGS30H | 10.7-11.2 | 1.07-1.12 | 8.8-10.4 | 700-828 | >25.0 | >1990 | 28-31 | 223-247 | ||

| XGS32M | 10.9-11.5 | 1.09-1.15 | 4.0-10.1 | 318-804 | 398-955 | 5.0-12.0 | 29-32 | 231-255 | ||

| XGS32 | 10.9-11.5 | 1.09-1.15 | 9.0-10.5 | 716-836 | >12 | >955 | 29-32 | 231-255 | ||

Ask for a quote

![]()

People who visited this page also visited these LEYUAN pages: