How we service our customer, help him to finish his idea and optimize the products to meet the efficient cost.

We have received an client enquiry regarding magnet parts, requesting

Length of magnet: l.= 80 mm

Diameter: d=9 mm

Return Force: F=20/30 N

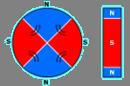

Multiple magnetization on the outer diameter as shown in figure

According to our experience, for a 9mm diameter magnet to reach a return force of 30N, it has to be a sintered neodymium iron-boron magnet. However, there is no manufacturer in China capable of manufacturing a four-poles magnetic tube.

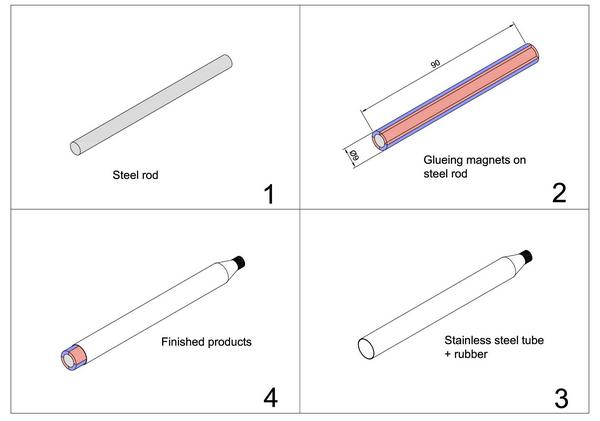

We have devised a different solution to address this, which is to make and then stack tile-shaped magnets one by one according to the magnetic circuits requested by the client. We provided a rough production process to elaborate what we intend to do.

- Step 1: Make a steel rod.

- Step 2: Glue tile-shaped magnets one by one on the rod into the magnetic tube as requested by the client.

- Step 3: Make a stainless steel tube with an inner diameter larger than the outer diameter of the rod made earlier.

- Step 4: Insert the said rod into the tube to complete the magnetic tube.

This proposal allows us to deliver magnetic circuits as requested by the client, and the return force can be tuned through adjusting the thickness of the tile-shaped magnets. However, this proposal was rejected by the client as it was costly.

After having full understanding of the client’s intended use for the magnetic tube, we know that the most crucial part of the project is the return force, which allows us room for designing the optimal solution to the problem.

- A four-poles circuit is unnecessary, hence we change it to a two-poles one.

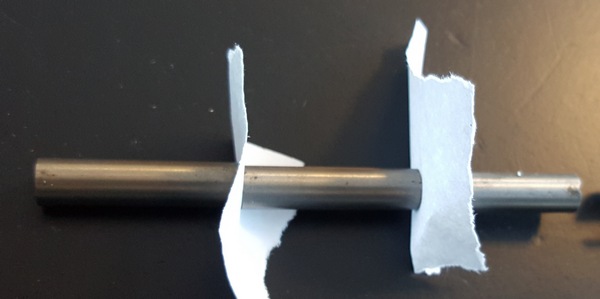

- A 90mm long rod magnet can only be wire-cut in the manufacturing process, which is costly. As such, we will separate it into three sections, allowing the magnet to be cut conventionally, reducing cost significantly:

- How do we install all three sections of the rod magnet, allowing them to be unaffected by repulsive force and kept in a straight line? We designed a fixture to reduce difficulty of assembly, and increase consistency.