Introducing how Leyuan Magnets making magnetic separation assemblies. We usually use 4 kinds of welding solutions for different kinds of application.

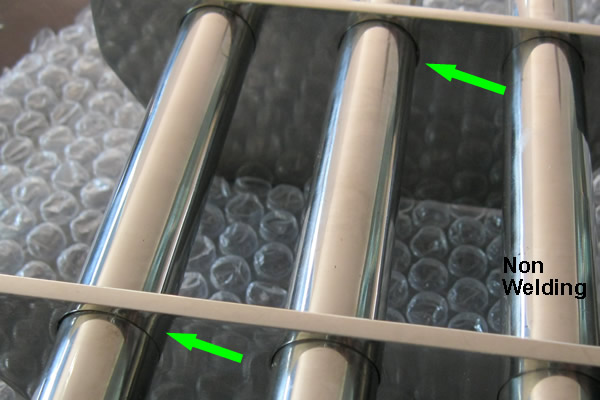

Non Welding

The magnetic tubes are inserted through the stainless steel support plate, but are not welded at the intersections. As such, it is easy to imagine that the tubes can fall off easily. In order to solve this, we embedded a pin on the plate to have the tubes fixed. This method of assembly is fast and has low cost. However, the bond strength is not as high.

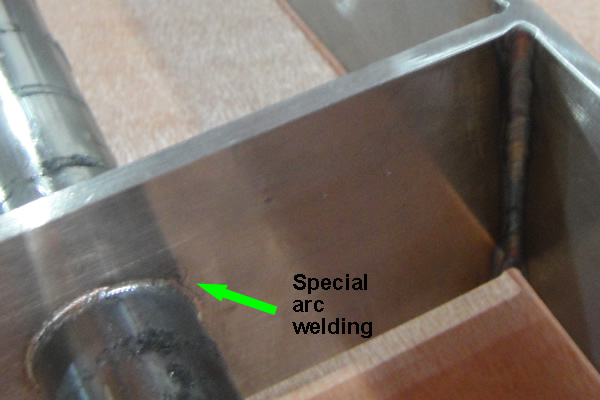

Arc Welding

The method is also known as Tungsten Inert Gas (TIG) welding. This welding method has a deep weld puddle and gives the best bond strength. However, arc welding is susceptible to effects of the magnetic field, which makes high precision operations very difficult to accomplish. As such, spot welding is usually employed. This allows for quick assembly, but has large welding joints which makes it difficult to be polished.

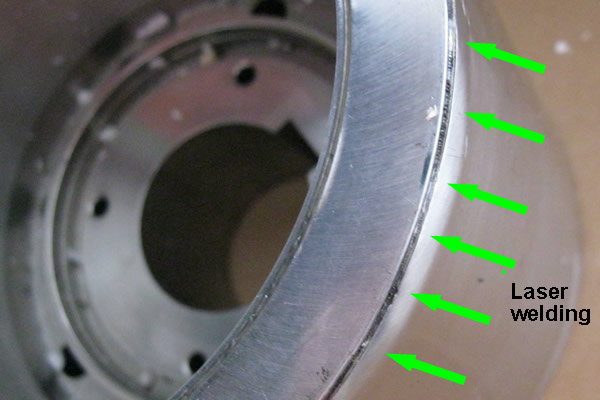

Laser Welding

Automatic laser welding is unaffected by magnetic field and has looks good after welding, making polishing afterwards unnecessary. However, it has a high equipment and maintenance cost for making magnetic grate.

Cold Welding

Cold welding stands between arc welding and laser welding. It gives greater bond strength than laser welding, and is easier to control than arc welding. The diagram above shows our use of cold welding to weld the intersection of the tube and the plate. This allows for a clean finished product with no hygiene issues, making it the top choice for magnetic filtration used in food industries.

We use these facilities to make magnetic separation and magnetic assemblies. We will choose the most appropriate facilities and optimized industrial solutions upon receiving your diagrams or ideas, based on our extensive knowledge and experience, to create your product.

You may also interested in 4 Secrets You Might Not Know When Purchasing Magnetic Separations.

We at Leyuan Magnets are good at making magnetic assemblies, especially when they are related to magnets and stainless steel systems. If you have any questions, please contact : sales@leyuanmagnets.com